Austempering is an isothermal heat treatment process which significantly improves both the strength and wear resistance of ductile iron whilst retaining the impact resistance and ductility for which the material is noted.

The minimum mechanical properties are shown in the following table which is the ASTM A897M-90 A.D.I. specification:

| Grade | Yield Strength Rpo,2 MPa Min. | Tensile Strength Rm MPa Min. | Elongation % Min. | Unnotched Impact, J Min. | Hardness BHN* |

|---|---|---|---|---|---|

| 850/550/10 | 550 | 850 | 10 | 100 | 269-321 |

| 1050/700/7 | 700 | 1050 | 7 | 80 | 302-363 |

| 1200/850/4 | 850 | 1200 | 4 | 60 | 341-444 |

| 1400/1100/1 | 1100 | 1400 | 1 | 35 | 388-477 |

| 1600/1300/ | 1300 | 1600 | - | - | 444-555 |

Not mandatory for guidance only

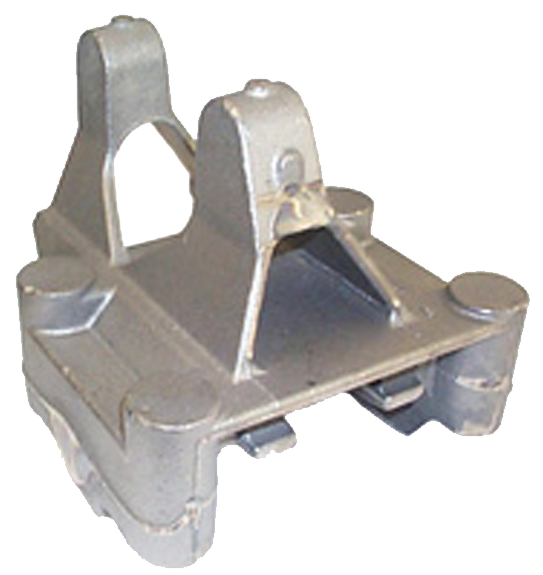

A.D.I. is a proven cost-effective alternative to cast and forged steel and offers the following advantages:

Weight Saving:

A.D.I. is 10% lighter than steel. Higher strength allows smaller sections than conventional SG castings, whilst retaining performance criteria.

Machining:

Nearness to nett shape reduces machining costs.

Tooling:

Tooling is less expensive with improved lead time when compared to forging dies.

Environment:

The amount of energy required to produce A.D.I. can be upto 50% less than steel casting and forging counterparts.

Piece Price:

As a conversion from steel castings, forgings and fabrications, A.D.I. can very often offer worthwhile cost savings.

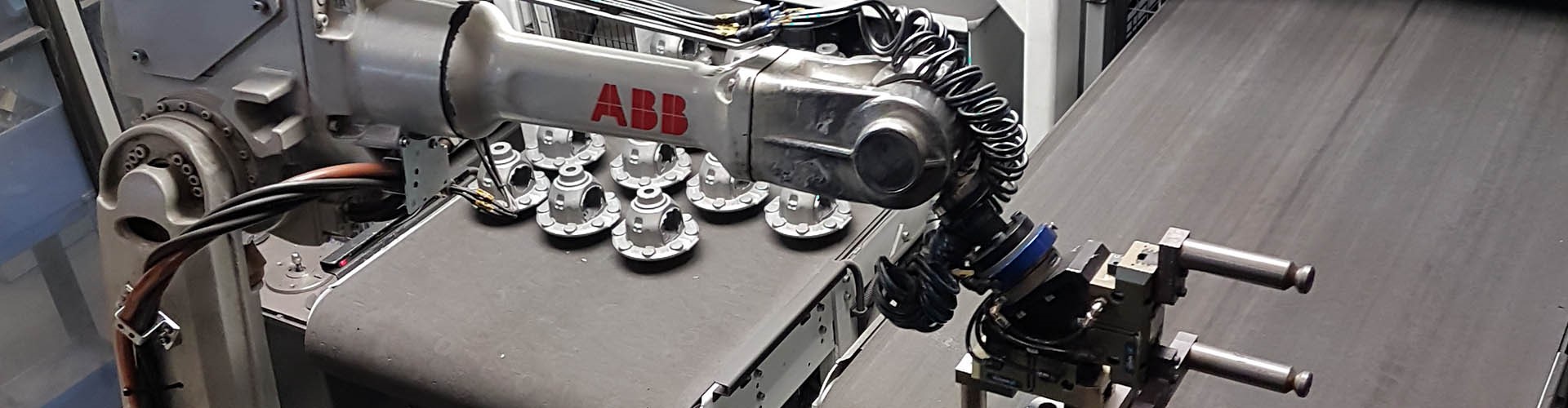

The Castings Plc Group, which has its own austempering plant, has experience in producing components for various applications within the agricultural, construction, automotive, trailer, mechanised handling and other industries.

We offer advice and technical assistance in ensuring the suitability of A.D.I. for each unique application, including prototype and pre-production development as required.

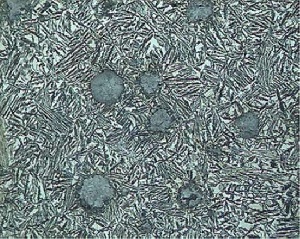

ADI Microstructure